Learn About HRC Fuses and Get Answers to the Most Frequently Asked Questions

To understand the importance of fuses, it helps to consider what happens without them. Without a fuse in the circuit, overloads, short circuits and overcurrent events can cause serious damage to connected electrical appliances, and in the worst cases, even lead to fires.

That’s why fuses are essential for protecting electrical systems. However, standard fuses have limited capacity. In contrast, High Rupturing Capacity (HRC) fuses can safely interrupt much higher fault currents without damaging equipment.

Their ability to handle high fault levels makes HRC fuses ideal for residential, commercial and industrial applications. In this guide, we’ll explore key aspects of HRC fuses and answer frequently asked questions.

Frequently Asked Questions About HRC Fuses

1. What are the key applications of HRC fuses?

HRC fuses are used across a wide range of sectors:

- Industrial Equipment Protection: High-voltage machinery requires robust protection. HRC fuses and holders are designed to withstand high rated currents and safeguard expensive equipment.

- Residential Fault Protection: While not typically used in general domestic settings, HRC fuses are suitable for specific residential applications requiring enhanced protection.

- Automotive Industry: EV HRC fuses protect vehicle electronics from short circuits and overcurrent.

- Motor Protection: aM and gM fuse-links protect motors from overload, extending their operational life.

- Transformer Protection: gTR fuse-links are ideal for safely interrupting high fault currents in transformers and distribution systems.

2. How does an HRC fuse work?

Like standard fuses, HRC fuses act as sacrificial components. They contain a thin wire (usually silver or copper) that allows normal current to pass. During an overcurrent event, the wire melts, breaking the circuit and preventing damage. HRC fuses are designed to absorb the heat generated, ensuring safe disconnection.

3. What types of HRC fuses are available?

There are three main types:

- NH Fuse: A single-use fuse, also known as a knife-blade fuse, commonly used in industrial and commercial settings.

- DIN Fuse: A cylindrical fuse built to DIN (Deutsches Institut für Normung) standards, widely used across European industries.

- Blade Contact Fuse: Designed for easy installation, these are commonly used in automotive and electrical systems.

4. What are the advantages and disadvantages of HRC fuses?

Advantages:

- High breaking capacity, ideal for demanding environments

- Cost-effective compared to other protection devices

- Long operational life with minimal maintenance

- Effective fault discrimination for improved protection

Disadvantages:

- Single-use only – must be replaced after operation

- Manual replacement required

- Slower tripping time than some circuit breakers

- Heat generation may affect nearby components

5. Can HRC fuses be used in both AC and DC circuits?

Yes, HRC fuses are suitable for both AC and DC applications. However, DC circuits have higher arc energy, so selecting the correct voltage and current rating is essential.

6. Where can I find high-quality HRC fuses?

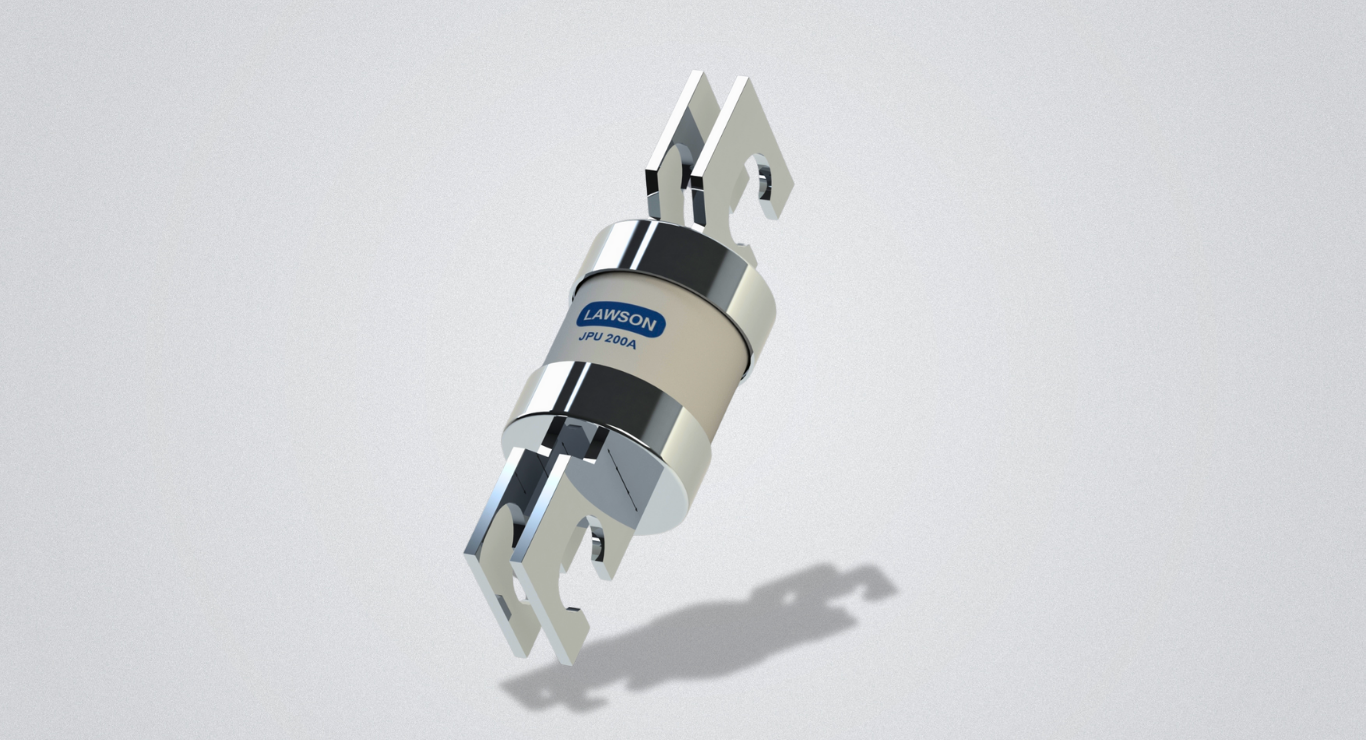

Choosing a trusted supplier is key. At Lawson Fuses, we offer premium-quality HRC fuses manufactured to global safety standards. Our team also provides tailored fuse solutions to ensure optimal protection without unnecessary cost.

Final Thoughts

Fuses are vital for protecting electrical and electronic systems from overloads, short circuits and other hazards. HRC fuses, with their high fault current capacity, are especially suited to industrial, automotive and specialist residential applications.

Need expert advice?

Contact us today for tailored fuse solutions for your industrial or residential needs.

For more news and information, please click here.