Understanding the Key Characteristics of a Fuse for Optimal Protection

A fuse is a vital component in an electrical circuit, designed to protect the appliances connected to it. Whether in industrial or residential settings, fuses are widely used across various applications. Essentially, a fuse acts as a sacrificial device that breaks the circuit during instances of overcurrent or short-circuiting. In simpler terms, the fuse melts or blows when there is an overload, thereby interrupting the circuit and preventing excessive current from reaching electrical equipment.

Fuses are designed differently depending on their intended application. For example, industrial fuses typically have a higher breaking capacity and are handled by trained or authorised personnel. In contrast, residential fuses are more cost-effective and used in household applications, often referred to as house service application fuses. This is why selecting the correct fuse for your specific application is crucial — and to do so, you must understand several key characteristics. In this blog, we’ll explore the most important ones.

Essential Characteristics of a Fuse

Choosing the correct type of fuse ensures protection against overcurrent and short-circuit conditions. Below are the key characteristics to consider:

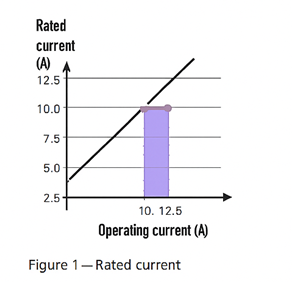

1. Rated Current

The rated current is the maximum RMS current a fuse can carry continuously without melting. It must be carefully calculated based on system requirements to ensure the fuse trips before any damage occurs. A general rule is to select a fuse with a rated current approximately 1.25 times the system’s operating current.

For example, if the operating current is 10 A, the rated current should be: 1.25 × 10 A = 12.5 A

This value is also known as In. Selecting the correct rated current ensures the fuse only breaks the circuit during genuine overcurrent events, maintaining the safe operation of your electrical system.

2. Voltage Rating

A fuse’s voltage rating must never be lower than the circuit voltage. Using a fuse with a lower voltage rating can result in dangerous arcing, potentially damaging equipment or even causing a fire. Always ensure the fuse’s voltage rating is equal to or higher than the circuit voltage.

For example, for a 220 V circuit, a 250 V or 600 V fuse would be suitable.

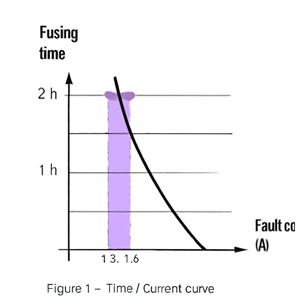

3. Time vs Current Curve

This curve shows how quickly a fuse reacts to overcurrent. The time it takes to break the circuit is inversely proportional to the current — the higher the overcurrent, the faster the fuse operates.

Understanding this curve helps determine the fuse’s behaviour in different scenarios. Fast-acting fuses are ideal for protecting sensitive electronic equipment.

4. I²t Value

The I²t value represents the energy a fuse can absorb before melting. It is calculated by squaring the current and multiplying it by time, expressed in A²s (Ampere-Squared Seconds).

- High I²t: Slower response, suitable for circuits with inrush currents (e.g., motors). These are known as slow-blow fuses.

- Low I²t: Faster response, ideal for sensitive electronics. These are called fast-acting or ultra-fast fuses.

Fast-acting fuses typically dissipate more power than slow-blow fuses.

5. Breaking Capacity

Not to be confused with rated current, breaking capacity is the maximum current a fuse can safely interrupt. It defines the upper limit of protection and ensures the fuse can break the circuit without causing damage during extreme overcurrent events.

6. Type of Fuse Element

The fuse element is the part that melts to break the circuit. It must be chosen based on the application:

- Copper and tin alloys: Common, cost-effective, with low melting points.

- Silver: Used in high-performance fuses due to its resistance to oxidation and reliable performance. Silver elements offer:

- Low I²t

- Low cut-off current

- Low temperature rise

- Low power dissipation

7. Compliance with National and International Standards

Fuses play a critical role in safety, so they must meet strict standards. Always check for compliance with recognised regulations:

- IEC 60269-1: Standard for low-voltage fuses, ensuring quality and safety.

- IEC 60269-2: Extension for industrial fuses, suitable for professional use.

- BS 88: British Standard for robust, high-capacity fuses, ideal for compact installations.

- IEC 60127: International standard for miniature fuses, covering breaking capacity and time-current characteristics.

8. Types of Fuses

Choosing the wrong type of fuse can lead to poor performance, nuisance tripping, or inadequate protection. Here are the main types:

a. AC Fuses

Used in both industrial and residential settings to protect against alternating current (AC) overcurrent. Available in various sizes and ratings.

b. DC Fuses

Similar in function to AC fuses but designed for direct current (DC) circuits. They protect against overloads, short circuits, and unstable current conditions.

c. High-Voltage Fuses

High-voltage fuses fall under the AC fuse category and, as the name suggests, are used in high-voltage circuits. These fuses are commonly found in industrial applications and are often used to protect transformers.

d. Low-Voltage Fuses

Low-voltage fuses are widely used in residential, commercial, and industrial environments. You’ll find them in households, vehicles, and small electrical appliances. These are typically fast-acting fuses, offering efficient protection against short circuits.

e. Cartridge Fuses

Cartridge fuses are primarily used in AC circuits, although they can also be suitable for DC applications. They offer excellent value for money and are a cost-effective, reliable solution. Cartridge fuses are easy to replace and provide dependable protection across a range of uses.

f. Other Important Fuse Types

| Type of Fuses | Applications | Where to Use? |

| gFF | Quick-action fuses for low-voltage circuits | Ideal for protecting sensitive electronics |

| gG | General-purpose fuses | Adequate protection from both overcurrent and short circuits |

| gR | Protection for semiconductor devices | To protect semiconductors, used in both AC and DC circuits |

| aM | Short circuit protection for motors | When you only need short circuit protection, without overload handling capabilities |

| aR | Used in circuits to protect semiconductors | Ideal to protect extremely overcurrent-sensitive semiconductors |

Choose Lawson Fuses for Enhanced Safety and Superior Quality

One often-overlooked factor when purchasing a fuse is the manufacturer. Selecting a trusted and compliant fuse manufacturer offers several key benefits:

- Ensures adherence to industry regulations and supports safety audits.

- Guarantees high-quality materials for effective protection against short circuits and overloads.

- Reduces the risk of fuse failure through consistent manufacturing standards.

At Lawson Fuses, we manufacture products in accordance with both national and international standards. Our extensive experience ensures the quality and reliability of every fuse we produce. All products undergo rigorous quality checks, and our range includes:

- Fuse links

- Fuse holders

- PV fuse links

- Street lighting fuse links

…and many more.

You can browse our full product catalogue or contact our customer care team for assistance.

Conclusion

Understanding the key characteristics of a fuse is essential for ensuring the safety and efficiency of any electrical system. From rated current and voltage ratings to compliance with international standards, every detail matters when selecting the right fuse for your application.

Whether you’re working on a residential or industrial project, choosing the correct fuse type is critical. It can make all the difference in protecting your systems and extending the lifespan of your equipment.

At Lawson Fuses, we prioritise quality, compliance, and performance. Our fuses are precision-engineered and rigorously tested to meet global standards. So, when it comes to safeguarding your circuits. Don’t compromise.

Choose smart. Choose Lawson Fuses.

For more news and information, please click here.